Bulletproof roofs covered by sheer brilliance with aluminium roofing sheet supplier

Sheet, the most widely used form of aluminium, is found in all of the aluminium industry’s markets. In packaging, sheet is used to manufacture panels for automobile bodies and tractor trailers. Sheet is used in appliances and cookware.

Countless everyday objects are fabricated from sheet metal. Thickness can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6mm(0.25 in)are considered plate steel or “structural steel.”

Sheet metal can be used as a roofing material, to make flashing for roofs and to make rain gutters. Inside a building, duct work and furnaces can be made from sheet metal.

Sheet metal is lightweight and can be conveniently stacked. This also means sheet metal is extremely durable. Infact, many homeowners choose metal roofing as a direct result of its durability. The most commonly purchased metals include aluminium sheets and stainless steel.

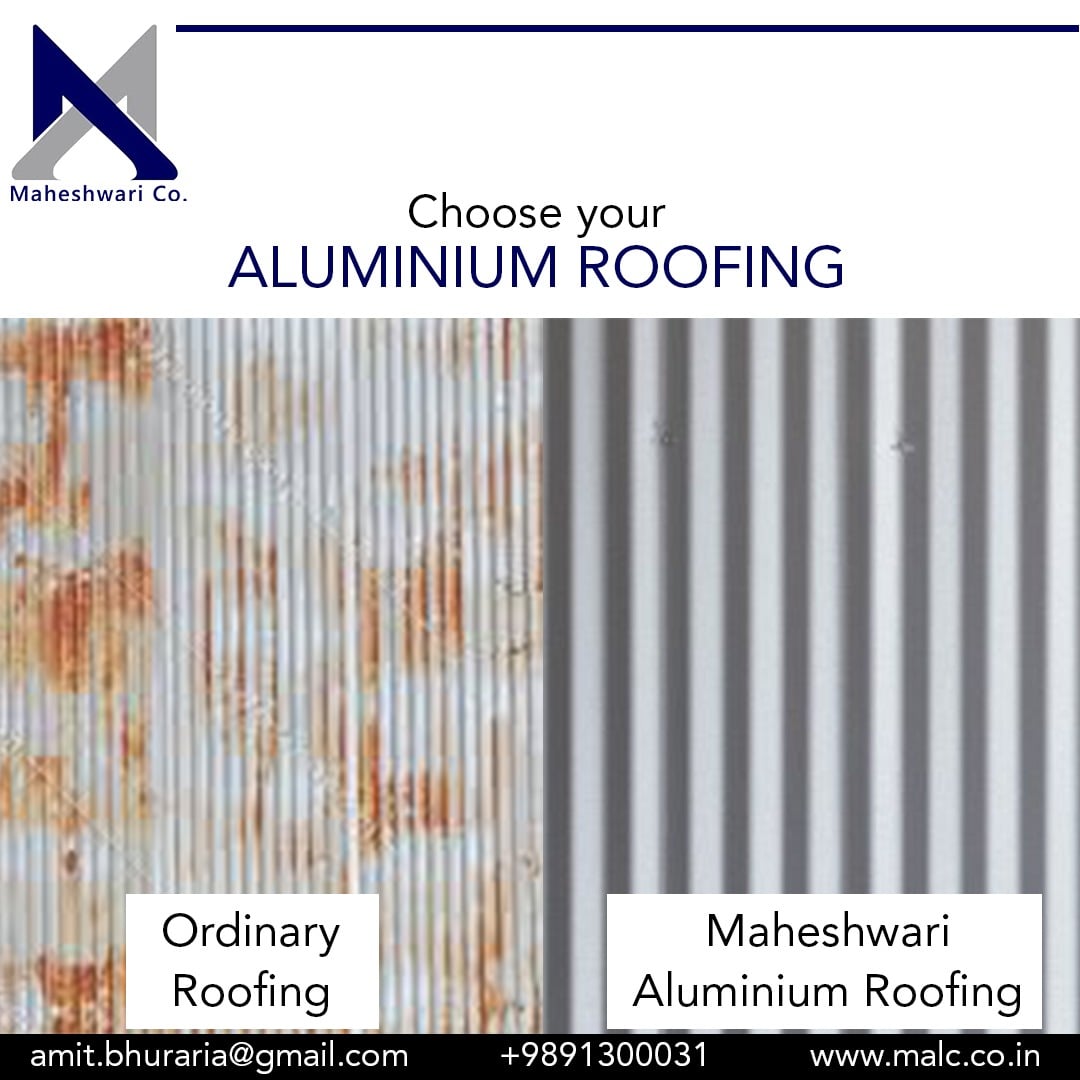

Maheshwari Company Pvt. Ltd.is one of the well known aluminium sheet supplier and aluminium roofing sheets suppliers in India. They are known to offer a wide range of superior aluminium sheets which are available in various alloys, grades, and thickness. They are made from high-quality aluminium, these sheets have the wide applications in signage and aluminium composite panels.

Conclusion

To conclude, in a nutshell, aluminium roofing sheets are used in a variety of things both in and around a house and Maheshwari Company Pvt. Ltd is one of the best aluminium roofing sheet supplier.